3D Printing: SLA Form 3

Our Resin SLA printers are additive manufacturing process that selectively cures polymer resin by using an ultraviolet (UV) laser beam.

This type of printing is great for producing intricate prints with a matte-like resin finish.

SLA Form 3

Form 3 Formlabs

Bed Size: 145 x 145 x 185mm

Materials: SLA Resin

For 3D Printing Questions:

Please visit the lab during opening hours and bring your laptop and files.

PRICING

Standard Resins

$0.60 per ml + $10 set-up fee

Engineering Resins

$0.70 per ml + $10 set-up fee

BOOKINGS

If you want to print using the SLA Form 3, you must book online through 3DPrinterOS. Students are responsible for submitting their 3D printing jobs through this platform.

On the completion of the 3D Printing Induction, you will be added to our 3DPrinterOS lab workgroup which will grant you access to our 3D printers in the online platform.

Use your Sydney University email address to log into 3DPrinterOS.

Booking Process.

Check our file prep checklist, to ensure you have set up your file correctly.

Check/repair your .STL file(s) in NetFabb.

Watch this video on how to use Netfabb.

Prepare your own .form Preform file.

Your 3D Printing request will be reviewed by staff within one business day. We can start your print sooner if you cost the print job yourself and have the funds ready in 3DPrinterOS. Use the job notes within 3DPrinterOS to confirm the expected cost for your print.

You will receive an email when the job notes are updated within 3DPrinterOS. Please reply promptly to any questions to keep your place in the print queue.

Prepare your print in PreForm

Step 1: Install PreForm

Step 2: Open .3mf or separate .stl files in Preform

Each separate body will need to be its own .stl or .obj file. This will allow you to independently rotate and move each body for optimal printing. Preform has copy, mirror, scale, and delete tools.

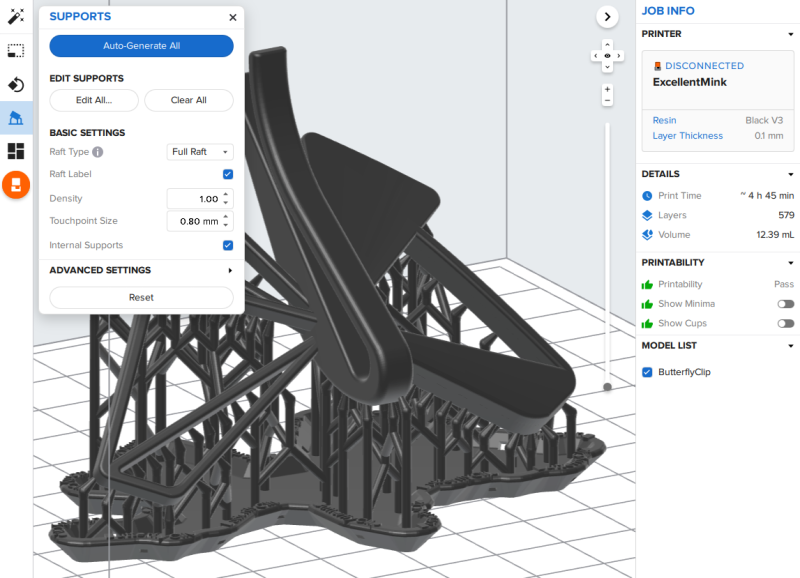

Step 3: Select material & layer height

The material running on each printer can be found in 3DPrinterOS. We run a fast 0.1 mm layer height unless there is good reason to print on the slower higher quality settings. This can be detailed in your job notes.

Step 4: Orient, support and layout your models

The Magic wand button will process through the orient, support and layout icons with one click. DMaF only uses full rafts when printing.

We recommend you learn more about best practices that go into orienting and supporting a model. Unlike FDM printing, SLA parts are best oriented on an angle to the print bed.

Step 5: Check printability

You will need to see the three green thumbs up symbols under the printability tab. If not, inspect models for unsupported minima and suction cups with the Slicer tool. You might need to add more supports or re-orient your model to improve printability and remove cups.

Step 6: Save and upload your .form file to 3DPrinterOS

The top right details tab has the ml of resin needed for your print. You can use this information to calculate how much your print will cost. When queuing the print in 3DPOS, confirm in the notes that you are willing to pay the amount you have quoted. e.g “ Please take $** from my 3DPOS account to pay for these * items in the Clear resin”.

Resource: Formlabs Support

Terms & Conditions.

DMaF will check over your file and let you know if we notice any obvious issues however we do not accept responsibility for issues that have not been fixed.

DMaF Lab staff are not responsible for ensuring that your design does not contain parts that will not print well, fit together or be strong – these are design decisions that should be considered by the student.

File Preparation.

Check you have prepped your file correctly before submitting a 3D Printing Order request by following these steps.

Design considerations for SLA printing:

Avoid creating internal spaces that resin cannot escape from.

The recommended minimum wall thickness is 0.8 mm or thicker.

Ensure all surfaces are ‘joined’ (type join) and that there are no holes or gaps. The model must be ‘manifold’.

All surfaces normal must face outwards. Use the ‘direction’ command (type DIR) in Rhinoceros to check.

Ensure there are not double surfaces.

Export your files as STL

Scale to print size

Move to origin (0,0)

Select individual objects and ‘Export Selected’

Save as type: 3MF or Stereolithography (.STL)

Select 0.01 accuracy

Save as Binary

If you have further questions, please visit the lab during opening hours with your laptop and files.