Metal Lab

A comprehensive workshop equipped for all forms of metal and plastic joining, forming & finishing.

This space offers users access to a wide range of metal fabrication expertise, under the guidance of our technical staff.

Accessing the Metal Lab.

Plan ahead and come prepared for your session with your DMaF Competency Card, USYD Student Card, closed shoes, your own PPE and any drawings or prototypes to help realise your project.

Our facilities.

The Metal Lab has a comprehensive range of metal and plastic tools and machinery available for use following the appropriate inductions.

DMaF operates with a colour coded system of Competency Levels on all machines. Successful safety induction completion allows access to the Level 1 machines. Level 2 and 3 equipment require machine specific inductions; please see technical staff to request an induction or check back here as induction workshop dates will be released throughout the semester.

As well as access to our range of tools and equipment we provide basic materials including various fastenings, finishes, sheets and rods. We encourage the re-use and repurpose of offcuts salvaged from previous projects.

We also have a broad selection of metal and acrylics in sheets, profiles and rods of various sizes for purchase.

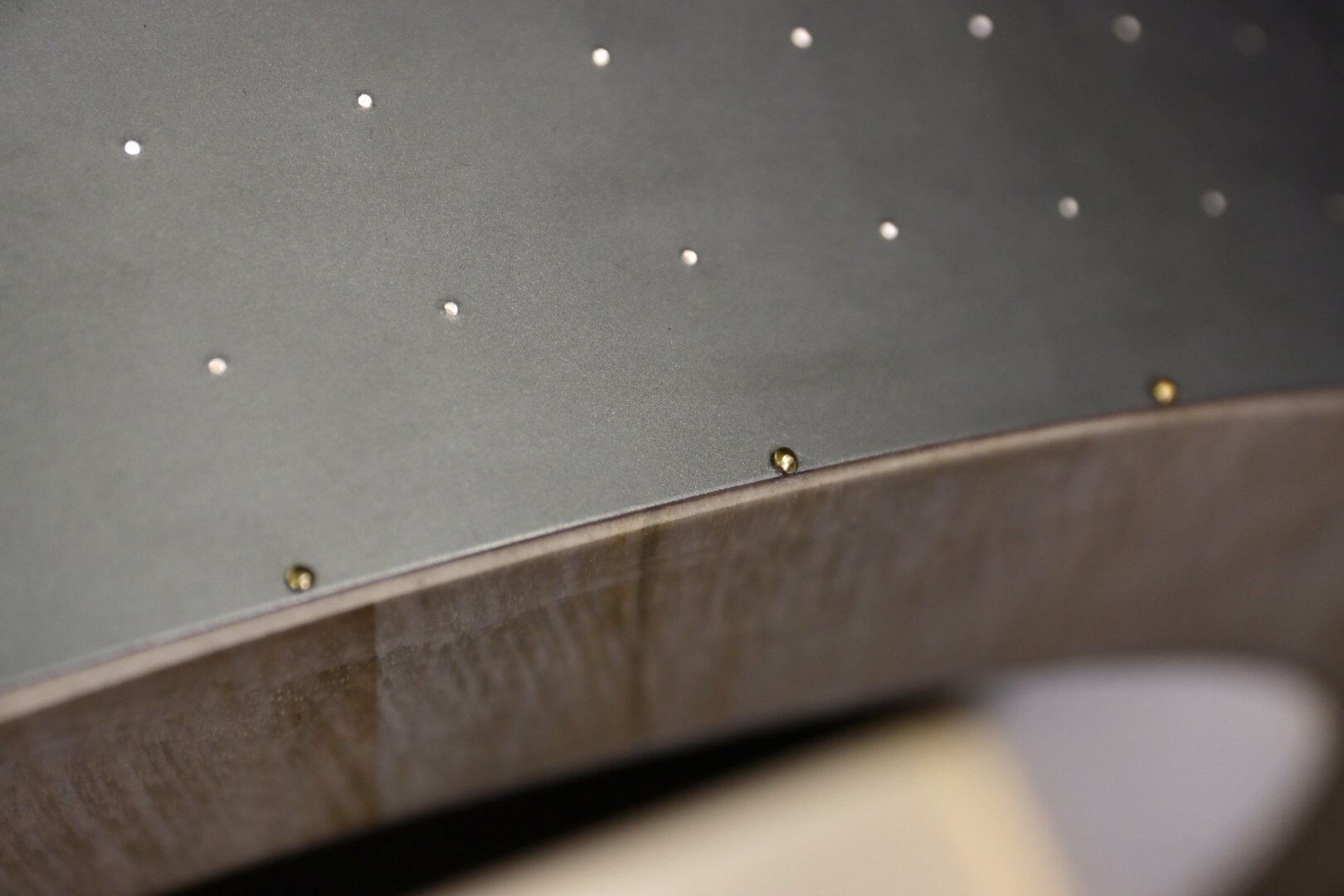

Water Jet Cutter

The DMaF Metal Lab has an OMAX ProtoMAX Water Jet Cutter for prototyping metals and other materials.

Visit the Water Jet Cutter page to submit files and see design requirements.

Metal & plastic processes.

Forming.

Forming of metal and plastics can be achieved through machining & cutting, and bending & pressing technologies. Our equipment covers reductive machining processes such as grinding, milling, cutting and sanding.

The lab also houses a small format numerically controlled Water Jet Cutter enabling the precise creation of prototype and model components. Bending & pressing utilises the ductility and elastic quality of sheet metal and plastics, achievable through manual methods such as pan braking, metal & acrylic folding or with machines like the Vacuum Former.

Joining.

Both permanent and temporary joining of metals and plastics can be achieved through a range of hand and machine fabrication processes.

Our equipment allows for permanent methods of joining including arc and spot welding, soldering, brazing and riveting. Temporary joins can be created for easy dismantling of components, achievable with fasteners, such as nuts, bolts, screws, clamps, cables, nails, hooks, rings and staples.

Finishing.

Machines and tools in the Metal Lab allow for a broad range of finishes, from highly polished to textural, depending on the abrasive or oxide, wax or polish used.

Belt sanders and grinders can grind, sand, polish, deburr, and contour various metals. The sandblaster creates uniform and customisable surface finishes on metal, plastic and glass. Hand-applied liquid finishes can polish, coat or patinate metal surfaces resulting in a broad range of visual and textural effects.

Machine competency levels.

Level one.

Level 1 equipment is accessible to all users who have completed the safety induction training. All L1 machines are labelled with a green Safe Operating Procedure (SOP) sign.

L1 equipment includes: Plastic & Metal Bandsaws | Drill Press | Pan Brake Metal Bender | Magnetic Bender | Metal Angle Bender | Metal Roller | Manual Guillotine | Spot welder | Soldering Irons |

Level two.

A Machine Specific Induction is required prior to Level 2 machine use; users can then operate the machine unsupervised. All L2 machines are labelled with an orange SOP.

L2 equipment includes: Sand Blaster | Fly Press | Punch Press | Cold saw | Electric Hacksaw | Perspex Bender | Hydraulic Press | Belt Grinder | Pneumatic Planishing Hammer | Vacuum Former

Level three.

A Machine Specific Induction is required prior to Level 3 machine use AND staff supervision is required during machine use. All L3 machines are labelled with a red SOP.

L3 equipment includes: Motorised Guillotine | Bench Grinder | Plasma Cutter | Mig Welder | Tig Welder | Stick Welder | Angle Grinder | Water Jet Cutter

Level four.

Qualified Technical Staff only.

All Level 4 machines are labelled with a black SOP.

L4 equipment includes: Metal lathe | Metal Mill